|

| October 06, 2015 | Volume 11 Issue 37 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

Ford F-150 features super alloy and mega-fast aluminum processing

2016 Ford F-150 (Lariat appearance package).

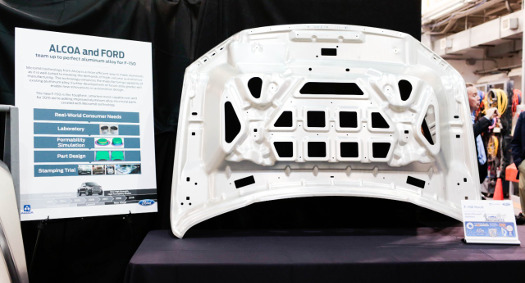

Ford Motor Co. and Alcoa Inc. are collaborating to produce next-generation automotive aluminum alloys that are more formable and design-friendly.

Ford will use Alcoa's Micromill material in multiple components on the 2016 F-150, becoming the first automaker to use the advanced automotive aluminum commercially. The two companies also announced on Sept. 25 a joint development agreement to collaborate on next-generation aluminum alloys for automotive parts using Micromill technology.

"Lightweighting enables us to design vehicles with great customer attributes, like the F-150, which can tow more, haul more, accelerate quicker, and stop faster than the previous F-150 and is more fuel efficient than ever," said Raj Nair, Ford group vice president and chief technical officer, Global Product Development. "This collaboration supports our continued drive for innovation, as we research automotive applications for even greater lightweighting."

The Alcoa-patented Micromill process dramatically changes the microstructure of the metal, producing an aluminum alloy with greater formability and strength.

Announced in December 2014, Alcoa's patented Micromill process dramatically changes the microstructure of the metal, allowing the production of an aluminum alloy for automotive applications that has 40% greater formability and 30% greater strength than the incumbent aluminum used today while meeting stringent automotive surface-quality requirements.

Additionally, Alcoa says automotive parts made with Micromill material will be twice as formable and at least 30% lighter than parts made from high-strength steel. The Micromill alloy has formability characteristics comparable to mild steels.

Micromill is the fastest, most productive aluminum casting and rolling system in the world, combining multiple technologies into a streamlined production system. A traditional rolling mill takes around 20 days to turn molten metal into coil; Micromill does it in just 20 minutes.

Video: Intro to the Alcoa Micromill process. (You can also view the video here.)

"This high-tech aluminum will give Ford a true material edge enabling greater design flexibility and better vehicle performance, making the concept cars of tomorrow a reality," said Klaus Kleinfeld, Alcoa chairman and chief executive officer.

The increased formability of Micromill aluminum makes it easier to shape into intricate forms, such as the inside panels of automobile doors and external fenders. The increased material strength allows for the use of thinner aluminum sheet without compromising dent resistance.

Klaus Kleinfeld, CEO of Alcoa (right), and Raj Nair, Ford Motor Company's group vice president and chief technical officer, Global Product Development (left).

Collaborating on the future of aluminum alloys

Ford will begin using Micromill material in 2016 F-150 production in the fourth quarter of 2015, and plans to increase its use over the next several years on a range of vehicle components and future platforms. It is projected Ford's use of Micromill material on its vehicles will more than double from 2016 to 2017.

Alcoa's advanced alloys offer Ford the formability and strength required for greater flexibility in designing vehicles using complex parts. By using the highly formable material, parts constructed of multiple pieces can be manufactured as a single part, which reduces complexity and assembly time. Target applications for the material include critical-strength structural parts as well as exterior panels that must meet strict surface-quality requirements.

Ford will use Alcoa's Micromill material in multiple components on the 2016 F-150, becoming the first automaker to use the advanced automotive aluminum commercially.

Aluminum alloy produced using the Micromill process has already been validated by Ford engineers to ensure it meets the stringent requirements for producing high-quality parts, especially the kinds of complex structures that make up F-150.

"The door inner is one of the most difficult parts in automotive stamping," said Peter Friedman, Ford global manager of structures and stamping, Research & Advanced Engineering. "The ability to produce an alloy using Alcoa's Micromill technology to make that part is a real statement for how this process can benefit the automotive industry and Ford in particular.

The joint development agreement between Alcoa and Ford will further expand the existing suite of automotive alloys produced by Micromill technology for use on Ford vehicles. New alloys will improve design flexibility on lightweight parts and provide better vehicle performance, which in turn will help Ford produce the types of quality, lightweight vehicles customers want.

Sources: For Motor Co., Alcoa

Published October 2015

Rate this article

View our terms of use and privacy policy